Nabtesco Precision Europe GmbH is the world's largest and most recognized manufacturer of cycloid gears. high positioning, Precision and reliability. Minimal play and high shock resistance. All this makes them ideal for applications in many high-tech fields. Compact, precise and robust! More than 12 My. Transmission of Nabtesco are in use worldwide. In about 60 % of all industrial robots in the world they are used.

We will advise you for your application.

Operating principle of cycloidal drive:

|

Advantages of Nabtesco cycloidal gears:

- high nominal torque of 50 Nm up to 28’000 Nm

- small space requirements due to the compact design

- Big shock resistance (5-times the nominal torque)

- high stiffness

- extremely high precision (Hystereseverlust < 1 arcmin)

- low backlash gears

- low moment of inertia

- insensitive to vibrations

- low wear

- long life span

- the ideal gear for the servomotor

- The compact alternative to a direct drive

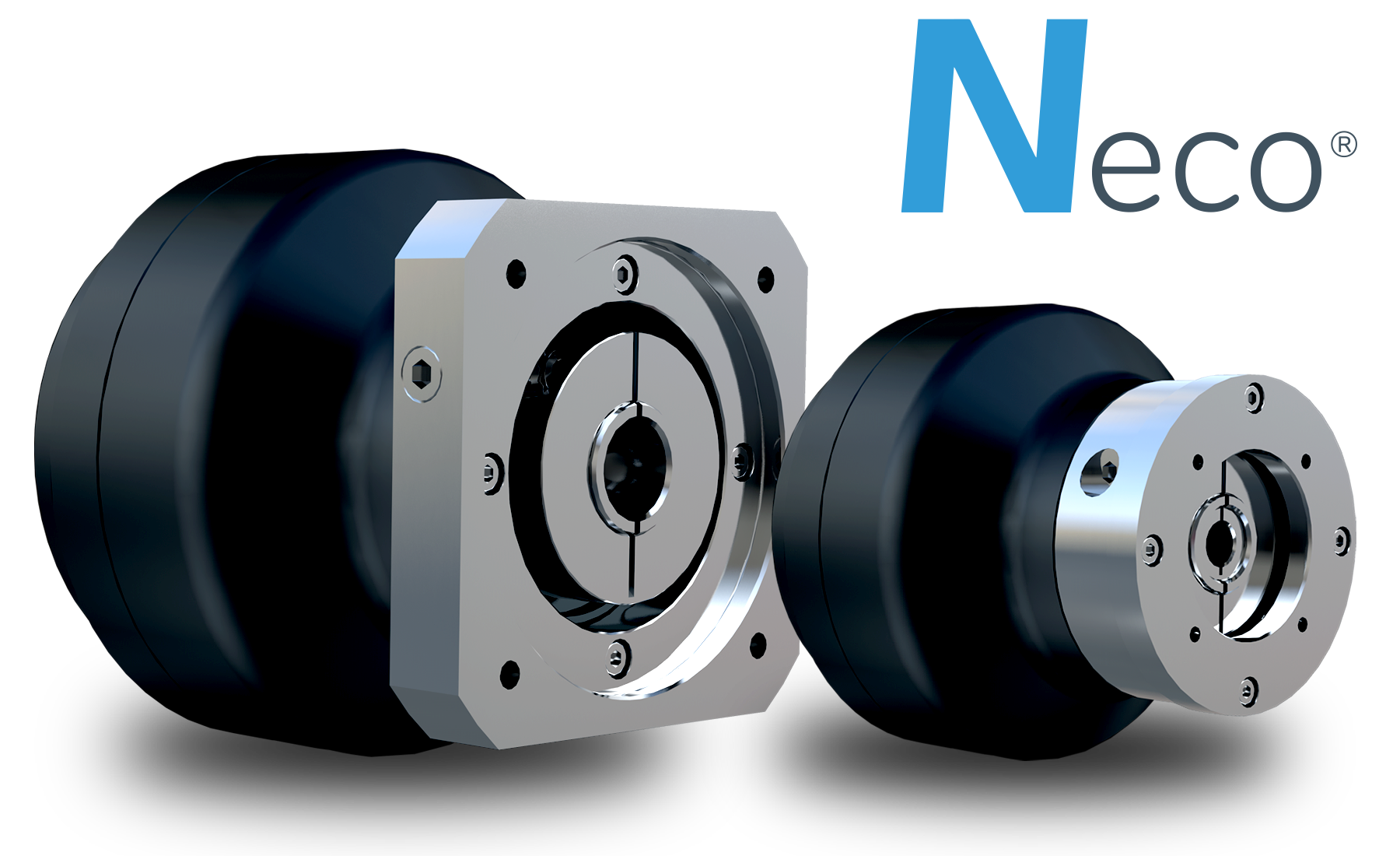

Brand new now: The Something®-Serie by Nabtesco

The precision gearbox with solid shaft from Neco®-Series have been consistently geared towards the needs of customers. It is a closed servo gearbox with maximum flexibility in the drive- and output adaptation. With their hygienic design, the gearboxes are also ideal for applications in the food industry., Pharmaceutical industry or medical technology.

Download the corresponding flyer here: Flyer – the something®-Serie

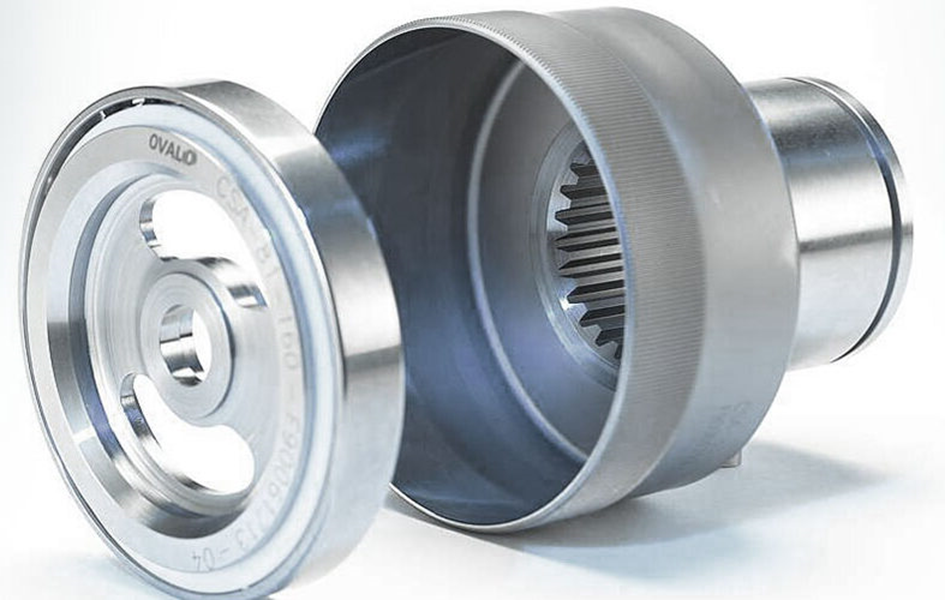

Ovalo-Wellgetriebe

Free of play, specific and efficient

The Wave gear of the brand OVALO, 100%subsidiary of Nabtesco Corporation, complement that Nabtesco-Ideal portfolio. The small precision gears are mainly at home in the lower torque range and are used everywhere, where high performance is required, but little space is available.

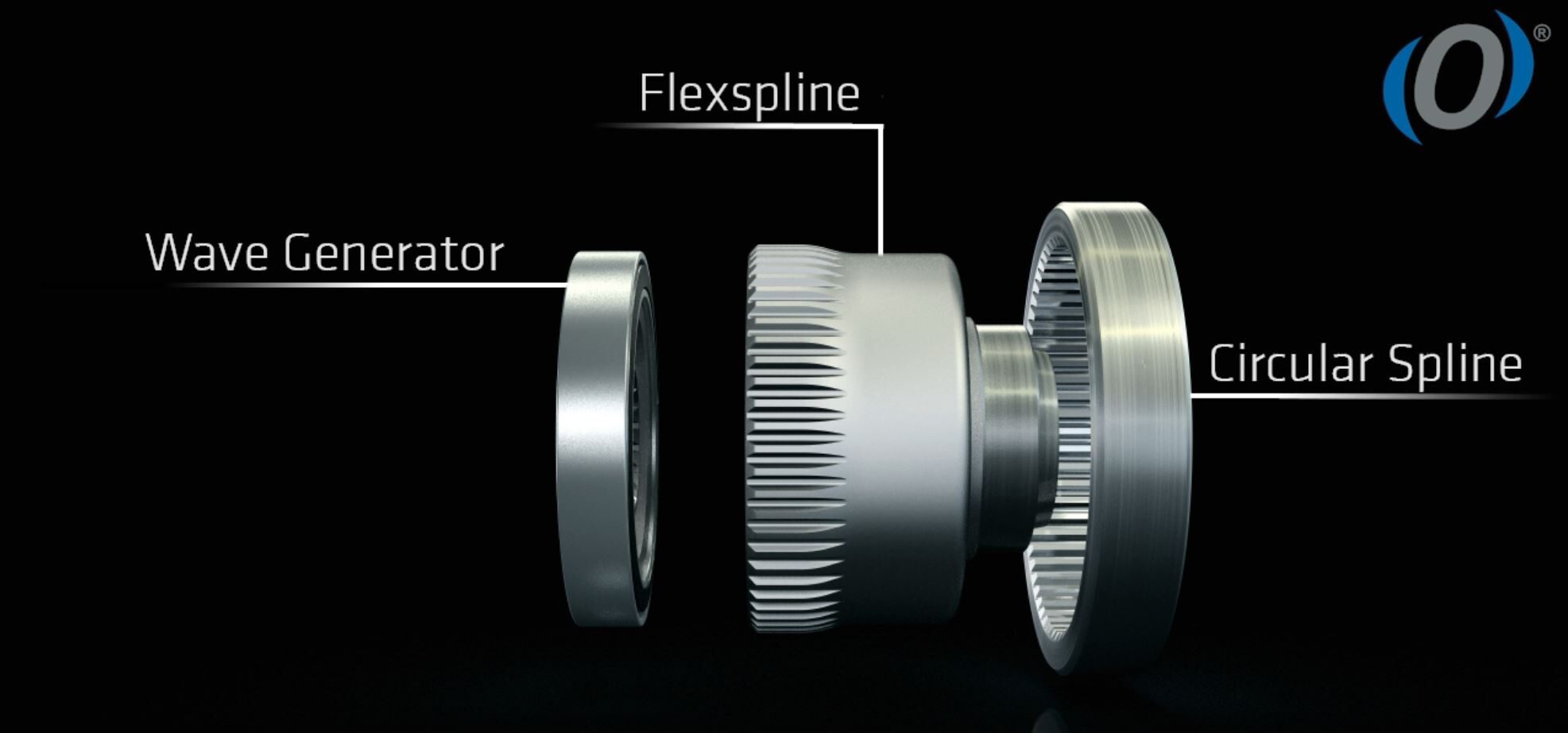

Technology wave gear

Wave gears consist of three elements:

- the ring gear / Circular Spline

- dem Flextopf / Flexspline

- the wave generator / Wavegenerator

Click on the picture to open the video “The principle of operation” in a new tab:

Product benefits:

- Freedom of play

- Excellent transmission- and repeatability

- Small dimensions and light weight

- High torque capacity

- High reductions in one step

- High efficiency

- High torsional rigidity

- Central hollow shaft possible

- High reliability and long service life

Customized wave gear

OVALO's trademarks are individually designed gearboxes. All wave gears are developed exactly according to customer requirements and the design is designed according to the requirements. In close cooperation with the customer, this creates highly efficient and economical drive solutions, the too 100 % are tailored to the respective application. The motto: The application is not adapted to the gearbox, but the gearbox meets the requirements.

-

- Individually designed wave gear

- Drive solutions tailored precisely to the application

- 100 % a perfect fit in terms of performance, Size and interfaces

About OVALO

Application examples for cycloid- and strain wave gears:

robotics:

With the RV-N series Nabtesco developed a compact, lightweight and powerful series. The precision gears are used everywhere there, where high torque outputs are required, but there is little room. The compact design is achieved by a main bearing with integrated inner ring. The gain of the eccentric shaft causes a very high power density.

Gears are a core technology in the design of robots. Therefore, particular attention should be paid to the choice and design of the appropriate gear. What is important and what designers have to consider, find out at Nabtesco Whitepaper "Gearbox design for 6-axis robots":

machine tools:

In machine tool workpieces and tools at high speed with micrometer accuracy must be positioned. Complete machining in a single setup prevents inaccuracies, which can creep through frequent repositioning the workpiece. Compared with planetary gears Nabtesco work gear by design much more precise, less wear and more reliable. Moreover, cycloidal drive come up with more compact dimensions of. equipped with Nabtesco transmissions axes, Tool changer or positioning tables have comparable performance data on how those with torque motors - and with much less effort and lower costs!

packaging technology:

The precision gear our RF-P- and RH-N series are for the food- and beverage industry as created: They feature a hygienic design and are easy to clean. Thanks to their high precision and power density, they are ideal for use in packaging machines, Filling or handling- and positioning systems such as SCARA, Delta- or palletizing robots. With its smooth surfaces and optimized seals servo gear units also meet the stringent hygiene standards of food- and packaging industry. On request, Nabtesco provides the transmission systems with special coatings or filled with food-friendly H1 lubricants.